HDPC Technology – Machine Park

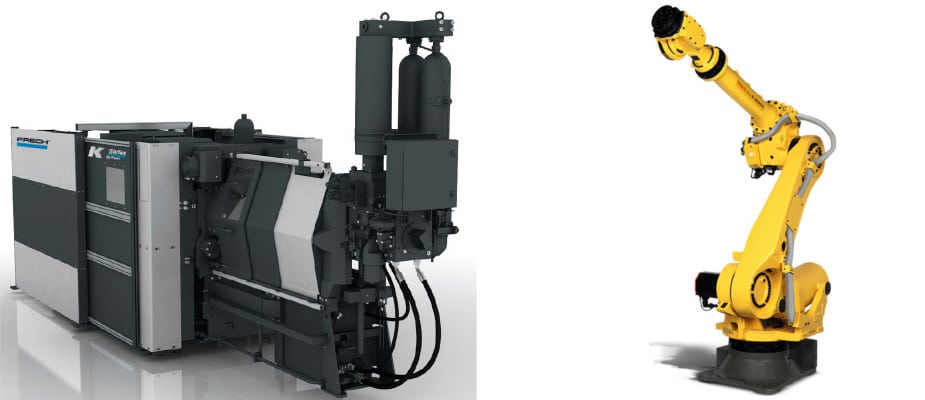

As the casting process forms the cornerstone of our production, we have curated a machine park comprising solely high-precision and dependable German-made FRECH casting presses. With a casting capacity ranging up to 1050 tons, we ensure that we consistently achieve our targeted product and process quality standards.

Additionally, our injection presses are equipped with top-tier, high-speed, and precise Japanese-made FANUC robotic arms to optimize efficiency and uphold our stringent quality standards. This comprehensive approach ensures that every aspect of our production cell is finely tuned for excellence.

Beyond casting, our commitment to quality extends to our post-processing capabilities, which encompass a range of essential steps including trimming, deburring, CNC machining, surface finishing, shot blasting, grinding, polishing, washing, and painting. Our dedicated assembly line further ensure that every product leaving our facility meets the highest standards of craftsmanship and functionality.

Manufacturing

Die Casting Cell

Aluminium Tooling Technology

Aluminium Melting Furnace

Feeding Systems

Injection Process

Full Automated Production Cell

Trimming Process

Engineering and Tooling

We take pride in our dedicated team of 21 skilled and experienced professionals within our Engineering and Mold Department.

Key activities of the team include CAD, CAM, Process Engineering, and MT (Mould & Tool) Manufacturing.

The extensive seniority within our team significantly contributes to the excellence of our engineering processes. Moreover, our team possesses valuable experience gained from collaborative design projects with Automotive OEM Customers and External Design Offices.

Our team utilizes cutting-edge software including CAD (Solid Works, Siemens NX), CAM (Auton Esprit), and Analysis (SolidWorks Plastics).

In terms of machinery, we are equipped with CNC Vertical Machining Centers, CNC-controlled EDM, EDM Wire Cut machines, Manual EDM, Milling Machines, and Lathes

Our Commitment to Excellence

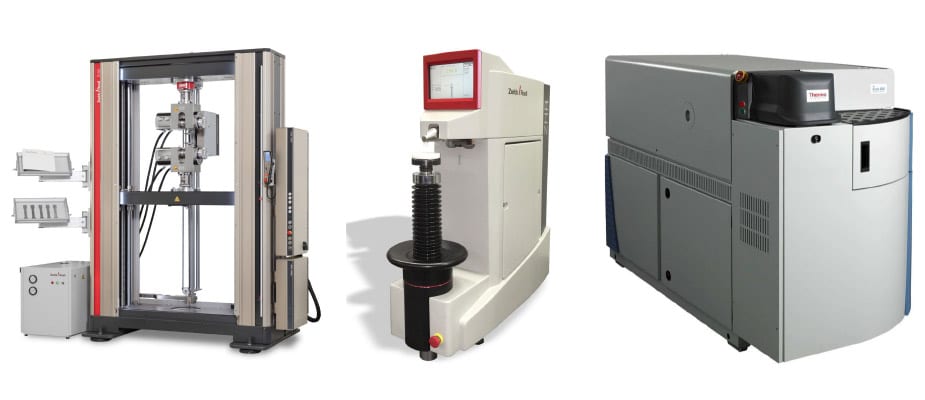

Our fully equipped laboratory plays a crucial role in the success of our business by conducting sophisticated tests and analyses to ensure that the quality of our products and processes meets our customers’ requirements consistently.

Operated by highly trained, capable, and experienced laboratory technicians, we utilize renowned brands of test equipment to carry out our analyses:

- 3D Digitizing: Steinbichler Comet Plus

- Video Measuring Machine: Mitutoyo QuickScope

- Optical Measurement Machine: Yamer Fastvision 3020M

- Tensile Testing: Shimadzu Comparison AG-X

- Spectrometer: Termofischer ARL iSpark 8820 /Bruker Q2 ION

- Microscope: Nikon LV 150

- Hardness Tester: Zwick ZHU187.5

- Surface Roughness Measurement Instrument: Mitutoyo Surftest SJ 301