Aluminium Extrusion

Extrusion is the process of placing cylindrical metal parts, namely wedges, inside a receiver and passing them through the matrix hole after the printing process. Thanks to this process, long sections such as pipes, strips and bars are obtained. In addition, the matrix hole is produced in the shape of the product section, by machines such as casting, rolling or wedge.

The process of removing aluminium by shaping it from a certain mold is called aluminium extrusion. In other words, aluminium extrusion is the forcing of aluminium alloy material from a mold according to certain measurements and profiles. Various products are obtained, for example strips with a diameter of 5,200 millimeters, inner diameters of up to 800 millimeters and 8 millimeters thick and more complex forms.

This process is in the form of a strong forging that pushes the aluminium out of the die, where the part comes out as a die and is then pulled through a runout. In addition, the extrusion process can be called as preheating the aluminum molds. Thus, aluminum is easily shaped and pressure pressure is reduced

Aluminium Extrusion Process

Aluminium is a silver-colored metal element with symbol Al and atomic number 13. It is generally found in nature as bauxite ore. It also has a high resistance to oxidation. This resistance is provided by the passivation feature. The place of aluminium in the world economy, which is used in the production of millions of different products by many sectors in the industry, is also very important. Aluminium is indispensable for the transportation, construction, space and aviation industries due to its lightness and durability.

The Aluminium Extrusion process is carried out in 10 steps. These steps are as follows:

- Preparing aluminium extrusion molds, heating them and making them ready for loading into the printing machine,

- Adjusting the aluminium billets according to the required temperature setting,

- Placing the billet length in the extrusion according to the conveyor length,

- Taking into the billet cassette,

- Removing the round billet billet from the mold according to the desired shape by pushing the punch billets towards the die,

- Using nitrogen, water and air cooling systems according to parameters such as thickness and surface of the output material,

- Cutting the outgoing profile according to the conveyor and stretching length,

- The resulting profiles come to room temperature,

- Stretching materials that come to room temperature,

- Cutting the stretched materials according to the desired length

Aluminium Extrusion Method

Direct Extrusion

Billet heated in direct extrusion is dropped into the sleeve and removed from the mold with a punch. The direction of movement of the billet and the punch is the same. Diversity is greater in direct extrusion compared to the indirect method. In addition, profile sections of different widths can be produced easily.

However, direct extrusion has some limitations. These:

- The printing power is much higher than that of other methods.

- The core and the hive can take more damage in this method.

- High temperature is a problem.

- It has a lower extrusion speed than other methods.

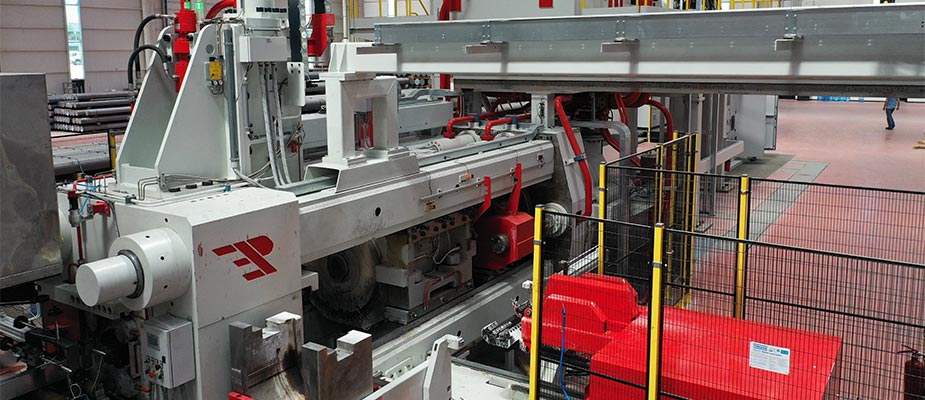

Erdoğanlar Aluminium uses a billet brushing system to keep the product quality high by cleaning the billets, four aging ovens with different hardness settings, die polishing machines to prevent extrusion lines in high-gloss products, and a speed control system to prevent color differences after anodized surface coating.

Aging Process

The aluminium element becomes a more durable and hard material as time passes. It takes a long time to wait for the product to harden in natural processes. Therefore, artificial aging furnaces are used to shorten the time. In artificial aging furnaces, the produced materials are subjected to a certain period of firing. Thus, the products become hard as if they have been waiting in nature for many years.

Alloys in the 2000, 6000 and 7000 series are placed in artificial aging furnaces. The aging process is accelerated by being brought to the most widely used t5 and t6 aging furnaces. This process can significantly increase the tensile strength up to 69Mpa. The process in question is a very important process in order to achieve the desired standards.

Why Erdoganlar Aluminium?

Erdoganlar Aluminium uses the latest technology and primary billets to produce the desired shapes with its expert and professional team. Emphasis is placed on tight mechanical properties and consistent surface quality to ensure the result is what you expect. In this context, the factory works with 4 Press machines. These are 1350 tons, with 1600 tons – 1900 tons – 3500 tons. With 4 press machines, approximately 2500 tons of monthly production is made.

In addition to these, there are billet brushing system, 4 aging ovens, mold polishing machines and speed control systems in order to increase the quality and flexibility of the product obtained, and to prevent the color imbalance that may occur after the surface coating (anodizing) process. The cooling process of the profile obtained after the heat treatment is also very important. For this, nitrogen, air and water cooling systems are used.

Erdoganlar Aluminium uses only high quality aluminium extrusion dies. Thus, the quality of the product obtained is top-notch. Heat and uneven pressure are easily controlled by expert team and equipment.

It is necessary to create a decorative appearance on aluminium profiles produced for visual purposes. This decorative visuality is achieved by a kind of oxidation. Oxidation occurs with anodized coating. There is an oxide layer thickness of 1-2 microns on aluminium. After this process, it increases to the level of 1-25 microns. Reaching this level of value not only makes the product more resistant to corrosion, but also creates a decorative appearance. The surface treatments applied to the product before the coating create the desired appearance as matte or glossy.