Operational Excellence is an inclusive management system that has the ability to effectively use the workforce, processes and technology to achieve sustainable success, provides leadership at all levels, and strengthens decision-making mechanisms.

Operational excellence at Erdoğan Aluminium is a core value implemented across all of our development and manufacturing facilities and reflects our commitment to total customer satisfaction. Our goal is simple: to be the preferred partner of our customers by offering innovative technology at the best cost and world-class production quality standards, while at the same time achieving sustainable and profitable growth.

We use a 5-Dimensional methodology below to ensure operational excellence and customer satisfaction.

1-Total Quality Management and Lean Manufacturing

In order to meet customer expectations in terms of product and service quality, we establish and maintain systems for employees and suppliers to deliver total quality.

We use the following tools in Total Quality and Lean Manufacturing management,

Continuous Improvement (PUKÖ) Cycle Brain Storming 5 Reasons Analysis Fishbone Diagram Pareto Analysis Quality Control Charts Kaizen , 5s

2-Customer Satisfaction and Complaint Management

We manage an integrated process to ensure customer satisfaction and resolve their complaints faster. With the joint participation of Sales, Design, Production and Opex units, we analyze the faults encountered in the product and system in detail and provide permanent solutions and improvements. In this process, we offer our customers the first complaint response within 2 days, our decision within 1 week, and our permanent actions with the 8D report within 2 weeks.

3-Supplier Management

Erdoganlar operates a supplier base system that integrates the most efficient suppliers in terms of innovation, quality, cost, delivery and risk management to provide high quality products and services.

Suppliers are evaluated and decided by 5 main criteria. As a result of the audits and performance evaluation of the suppliers, the suppliers are divided into 4 main categories (A-B-C-D) and managed.

4-Sustainability and Human

Erdoğanlar believes in leadership in Sustainability and strategically positions sustainability among its foundations. In this field, it primarily aims to produce new solutions for its customers and employees. Being sustainable while developing its business in an environmentally friendly and responsible manner is among its main goals.

Within the scope of sustainability;

- Implements a renewable energy program; Takes measures to reduce carbon footprint

- Implements Environmental Management System and develops environmentally sensitive projects,

- Implements the Occupational Safety Management System and continuously improves the Risky Areas,

- Observes the rights of the employees and does not discriminate,

It aims to develop its employees who are respectful to people and society and has adopted an ethical working method. implements and continuously improves its own “code of conduct – COC”

Erdoğanlar voluntarily participated in the Ecovadis Sustainability assessment in 2021. As a result of the Initial Evaluation, it took an average score among the participating companies and took steps to improve the system.

5- New Product Development Process

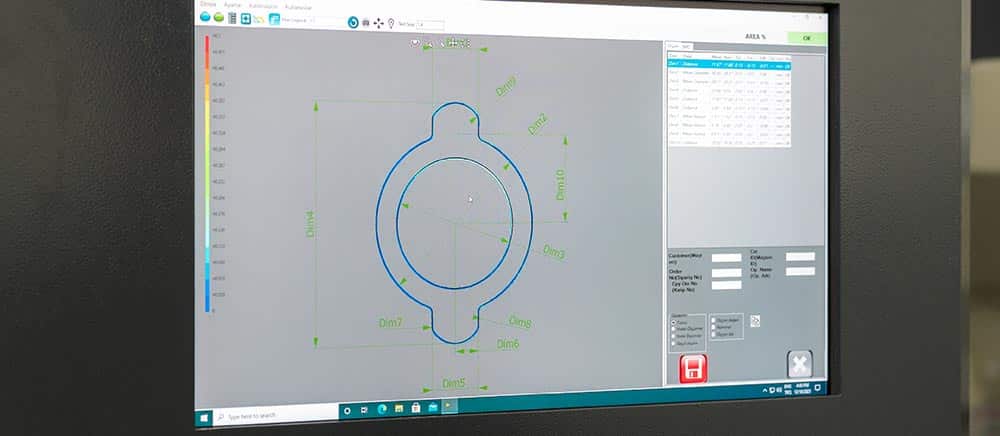

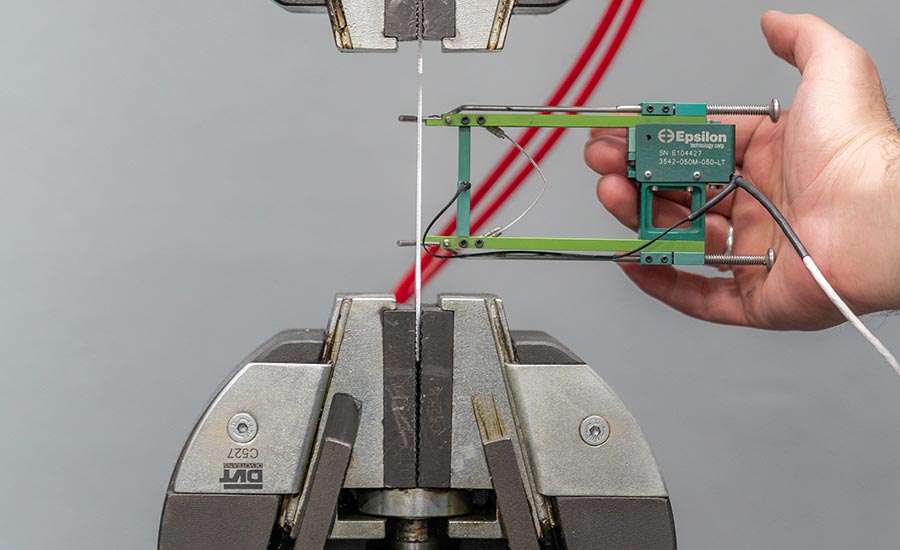

New product development and customer approval processes are carried out. An integrated process is followed for the production, control and delivery of the products requested by the customer with the best technology and equipment. From the customer’s new product-sample request to Technical Drawing, Mold Design, Production Process Processes, Control Processes, Packaging and Packaging processes, many processes are evaluated simultaneously and actions are taken to deliver the fastest sample and new product to the customer.

According to the customer’s new product and approval process demands, the PPAP (Production Part Approval Process) process is followed by our expert engineers and the reporting process is carried out in the format requested by the customer. PPAP studies at 5 different Levels can be performed.