Aluminium Fabrication Mechanical process

Mechanical process is the mechanical working of metals and the deliberate application of external force to the metal. This process is also known as plastic deformation. Because it is possible to work below or above the crystallization temperature of the metal component. Depending on the temperature used, hot work and cold work can be applied on the metal component, and the temperature at which new grains form in the metal is called recrystallization.

Mechanical process can give the desired shape and properties to all metals and includes rolling, forging and many other techniques. In the mechanical process, 90 degree angled cutting and slicing are made by means of single and double-headed saws with precise tolerance. In addition, thermal insulation barrier assembly, CNC machining centers, hole drilling drills and eccentric presses are produced in a quality way according to the wishes of the users.

In addition, the reasons for the mechanical processing of the metal component can be listed as follows:

- Improve grain size

- To control the direction of flow lines

- Shaping the original block or ingot to the desired size

Punch Process

Punch, also called punching, is shaping using punch press equipment to make a hole. This method, which brings various materials into sheet shape, is done with mechanical processing molds.

Punch transforms paper, sheet metal, vulcanized fiber and various plastics into sheet form. During this process, the punch passes from the inside of the work into the mold and any scrap pieces are placed in the mold through the hole. Depending on the type of material punched, the slug produced can be recycled, reused or thrown away.

In addition, a specially shaped punch is used to produce many usable parts from one sheet. This process, made with a specially shaped punch, is called blanking. Additionally, punch is an affordable method for creating holes on sheet materials with medium or high production volumes.

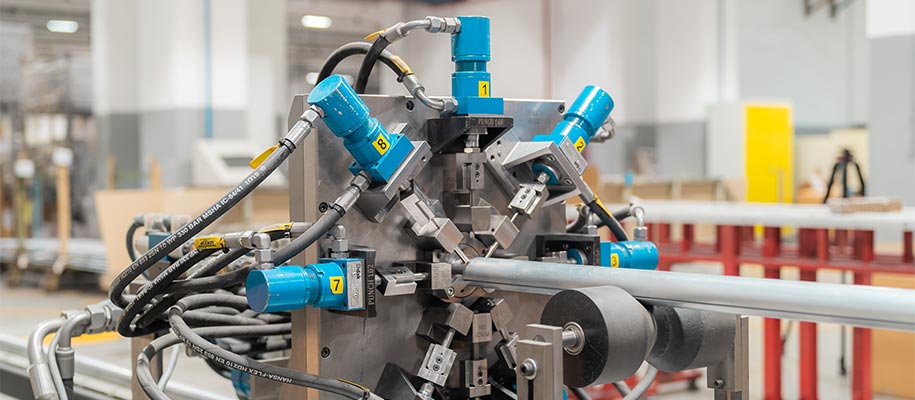

Special Punch Operations (Eccentric Press) / Pneumatic Punch / Hydraulic Punch

The eccentric press, which is a pressing process, is the presses that are made with an eccentric shaft from the center point, which is stimulated by an electric motor. The ram, which will perform the eccentric pressing operation, is connected to the shaft. In addition, it is necessary to move up and down to give the desired shape to the workpieces.This pressing process, also known as Pneumatic Punch, is done with a body and 3 molds. Generally, notching and mounting hole operations are applied to the horizontal profiles of the facade with these molds. These presses can be produced in various ways depending on the customer’s request.

- Round hole

- Square hole

- Special hole (Text-Logo. Vs.…)

- Countersunk drilling

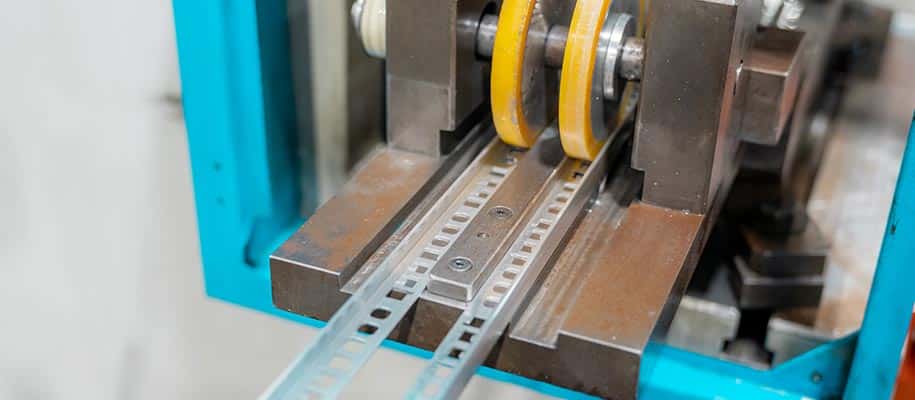

Standard Punch – Driven Dies

The standard punching process, which pushes the material to the press machine with a sliding system, is done with driver dies. The standard punch, which is a mechanical element, is also used to produce desired form properties and to expand the static stability of a sheet metal section.

It is also a machine used for embossing and punching flat sheet materials. Optional special drilling operations are also performed with these machines. These processes can be listed as follows;

- Round hole

- Square hole

- Special hole (Text-Logo. Etc.)

What are the operations that cannot be done with CNC-Punch?

Punch machines are used for efficient machining of metal components with high flexibility. CNC punching operations are generally preferred for small and medium-sized works. In addition, the CNC punch machine has quick-change tools and die carriers. This process is often used in studies where laser applications are insufficient.

These machines, which are controlled by numerical commands, are pre-programmed in which part of the molds will be processed on the sheet. There are a few processes that CNC punch machines cannot perform. These processes can be listed as follows;

Countersunk Drilling

Also known as countersinking, this process is the process of drilling cylindrical or conical slots into previously drilled positions. This process, which is carried out with improved countersink drills, is frequently preferred. There are various countersinking methods. These methods are preferred for making slots where the end parts of connection points such as rivets and screws will fit.

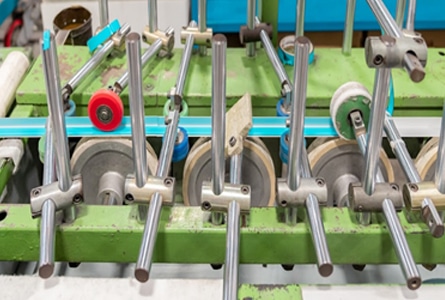

Notching

The notching process, called the lapping application, is used for lapping the middle register connection points of PVC and aluminium profiles. There are also special machines for the notching process. These machines have fast blade changing features.

Tapping

This application is the process of opening a thread slot with sharp tools called a guide in a hole. The process of drilling holes using a tap is called tapping. The operations performed without using tapping machines are called thread cutting. The various tapping methods are determined by the number of parts to be produced.

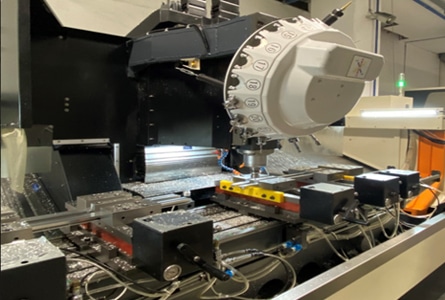

CNC Machine – 1

- 4 Axis

- Max. 4m(13,12ft), Min. 300mm (0,98ft)

- 11 Machine Tools

- 6 Clamps

- Sectors: Shower Enclosures

CNC Machine – 2

- 5 Axis

- Max. 6,5m(21,32ft), Min. 300mm (0,98ft)

- 12 Machine Tools

- 8 Clamps

- Sectors: Doors, Medical

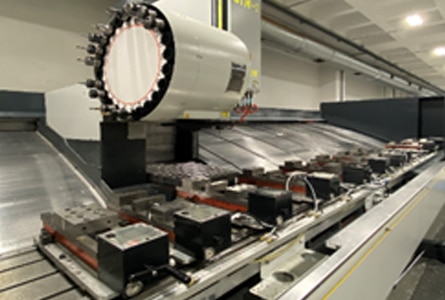

CNC Machine – 3

- 4 Axis

- Max. 6,5m(21,32ft), Min. 100mm (0,33ft)

- 24 Machine Tools

- 12 Clamps

- Sectors: Radiators, Heating Systems

CNC Machine – 4

- 3 Axis

- Max. 2,5m(8,20ft), Min. 100mm (0,33ft)

- 21 Machine Tools

- 6 Clamps

- Sectors: Shower Enclosures, Window Doors

What is Bending?

Bending is applied to shape the materials. This process, also called bending, shapes the workpieces. The types of operations performed on workpieces are known as drilling, cutting and welding. However, the bending process is also among these applications.

Bending with 3 Ball Machine

The 3-roll bending machine, which functions almost the same as the 2 batch bending machine, is used in metal sheet and sheet metal bending process. The main difference from the large 2 batch machine is greater control over the desired output.

Pipe Bending

This pipe bending machine, which enables the pipes to be reshaped, also performs the bending process. Machines can be diversified according to the characteristics and type of pipes. In addition, machines focused on the sector and raw materials make things easier.

Spinning Mold

Spinning dies, another sheet metal forming tool, press and pull on metal. With the punches placed in accordance with the molds, the selected product is pressed in different strengths and tonnages. After this application, pressing and pulling is done on the metal.

What is Cutting Group?

The cutting group, which is a part of sheet metal molding, is the method that is made with various applications in the cutting process during the production phase.

Precision Cut

Precision cutting, which is one of the special cutting methods; It is a cutting method that ensures that materials are produced smoothly, geometrically, with smoothly cut edges without cracks or tears.

Angle Cut

It is the operations that are done with the machines that support the profile cuts, usually with saws. Angle cutting machines, which are mostly preferred with bench models, are a process that should be done with predetermined metal thicknesses.

Brushing/Deburring/Chamfering Process (Actions Performed on Profile Head with Brushing Machine)

Cutting, which is a part of mechanical processes, is a sensitive application. Brushing is an application to remove the burrs formed on the edges of the cut materials during cutting. Brushing, also called chamfering, is a process performed at high cutting speeds without damaging the environment with dry cutting.

Laser Printing

Insulation Bar Assembly

- 50.000 meters per a day.

Adhesive Protective Holtmelt Tape Application

Third part Assembly

If you want your company’s mechanical processing needs to be met by a professional team, you can contact Erdoğanlar Aluminium right away.